Inventions and patents, years of experience and constant development shape the history of SunSquare. Each system is individually tailored to the local conditions and customer requirements. Through the creative use of the specially developed, largest mounting range in the shading industry, nothing seems impossible. More than 10,000 SunSquare systems installed worldwide reinforce the path that has been taken so far.

Functionality

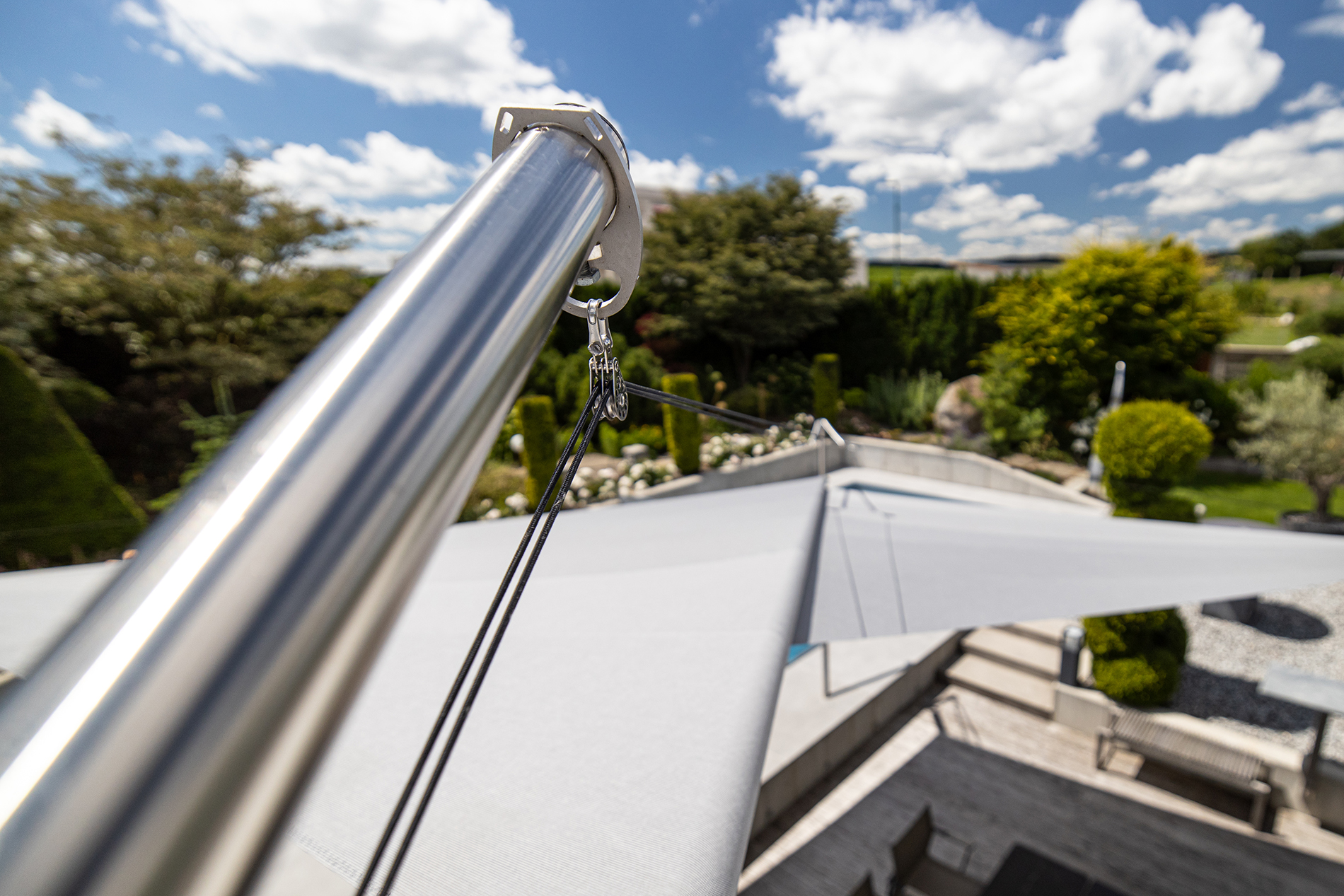

SunSquare® does not use non-industry components such as Yacht Accessories. All components match their function and are developed and produced for their usage.

drive & control

SunSquare® relies on Somfy motors and controls. Technical know-how-edge, quality and durability features of these products.

traction

SunSquare® trusts Dyneema® ropes branded TEUFELBERGER - the market leader in the field of modern and contemporary rope production. The 32-plait sheathing protects the Dyneema® core against UV radiation and abrasion - thus our ropes are always stained black - a design feature.

Standard

SunSquare® trusts in the EN-1090 certification and the company‘s internal factory testing of all components. All internal welding production steps as well as all the welding technicians themselves are certified according to EN-1090.

Installation

SunSquare® trusts in V4A-stainless steel grade 1.4404 and 1.4571 - the increased resistance to corrosion and pitting predestined these steels for use outdoors. With tube wall thicknesses of 3.6 mm and partly internal steel cores with 12 mm wall thickness, the necessary dimension for our the supports is even exceeded for our use.

SunSquare® can fall back on its wide portfolio of fixing systems made of stainless steel or aluminum components. The supports are individually manufactured as floor or wall supports for the respective situation and requirement.

Various ground plates allow mounting on concrete. Screwing dowels can be installed into grown soils.

SunSquare® NIROLINE - the most extensive and complex fixing system on the sun sail market. Solid stainless steel. Glass-bead blasted surfaces. Loved by our customers - admired by architects and engineers. NIROLINE guarantees power transmission. WM6010, WM2 6010, GPV 60, WK 6010, ... etc. And if NIROLINE exceptionally does not meet the requirements, a special solution will be found.

Sail material

SATTLER

SunSquare® and SATTLER SunTex - a common path for decades. Here is an overview of the possible acrylic cloth qualities.

- Colours SATTLER 314 - water repellent, not cleanable, 290 g/m²

- Colours SATTLER 320 - water repellent, not cleanable, 290 g/m²

- Colours SATTLER 321 - water repellent, not cleanable, 370 g/m²

- Colours SATTLER FIREMASTER 324 - water repellent, not cleanable, flame retardant, 400 g/m²

Acrylic cloths must never be treated with high-pressure cleaners, as this can damage the impregnation. We also recommend that you only roll in damp canvas once it has dried out and remove loose dirt regularly to prevent stains.

DICKSON

Orchestra acryl cloths are the complement to the SATTLER garments.

- Colours DICKSON Orchestra - water repellent, not cleanable, 290 g/m²

- Colours DICKSON Infinity - water repellent, not cleanable, 290 g/m²

Acrylic cloths must never be treated with high-pressure cleaners, as this can damage the impregnation. We also recommend that you only roll in damp canvas once it has dried out and remove loose dirt regularly to prevent stains.

SERGE FERRARI

Soltis Towels of Serge Ferrari are PVC-coated polyester fabrics that can be cleaned easily.

- Colours Soltis 86 - pure sun protection, B1, Q1, permeable to water, 14 % perforation in the fabric, cleanable

- Colours Soltis 92 - pure sun protection, B1, Q1, permeable to water, 8 % perforation in the fabric, cleanable

- Colours Soltis W96 - sun and rain protection, waterproof, cleanable

Sail

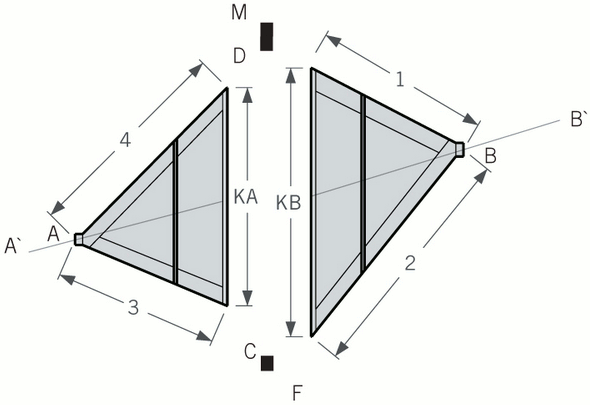

Triangular Sails (SQ-System)

The beginning of the SunSquare journey. The first SunSquare systems were based on the geometry of a triangular cloth.

Triangular sails (SQ) allow a shaft length of 13 m (max.) with a maximum extension length of 7 m (in one direction) and can be manufactured as a batten or radial sail.

Triangular sail as a batten sail

The SunSquare battensail has been manufactured since 1993 - without any changes. The sailing tracks that run parallel to the shaft ensure the traditional SunSquare look.

The fiberglass sail battens give the canvas a heavier character and contribute to the typical sagging appearance.

Triangular sail as a radial sail

The SunSquare radial sail has combined the advantages of the classic sail with a contemporary look since 2012.

By eliminating the battens, the susceptibility to damage the sail and the weight of the canvas are reduced. As a result, the sail sags less and there is an optimized dynamic appearance. This dynamism is supported by the radiantly approaching sailing tracks.

A hollow cut of 2 % reduces the sail area minimally.

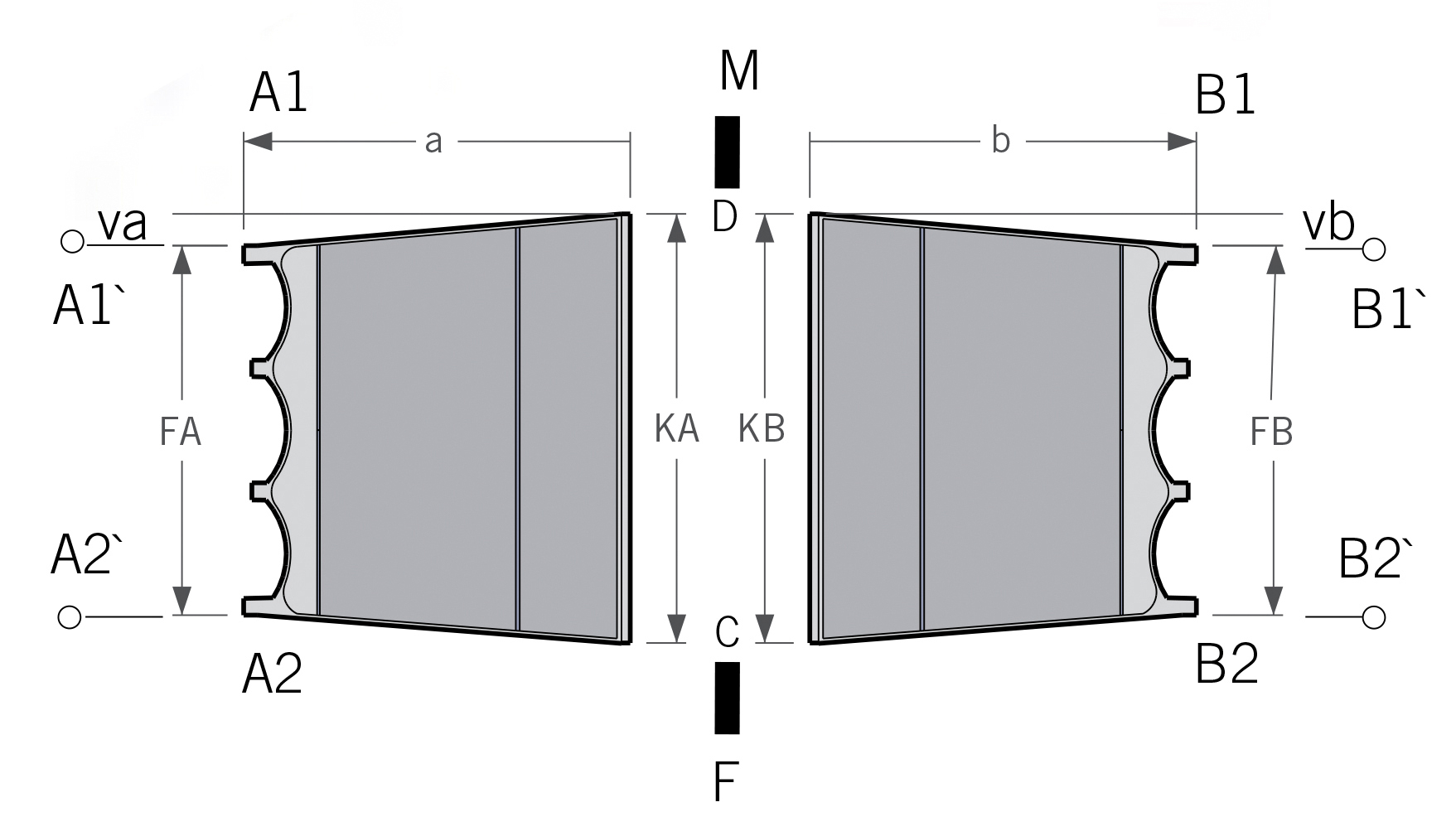

Rectangular Sails (AX-System)

Rectangular sails (AX) allow a shaft length of 5.8 m (max.) with a maximum extension length of 7 m (in one direction) and can be manufactured with battens or as a zigzag version.

Rectangular sail with battens

The fiberglass sail battens optimize the winding behavior.

Rectangular sail in zigzag cut

The zigzag cut was developed in order to reduce the wear-prone of the batten pockets.